Vision Technology

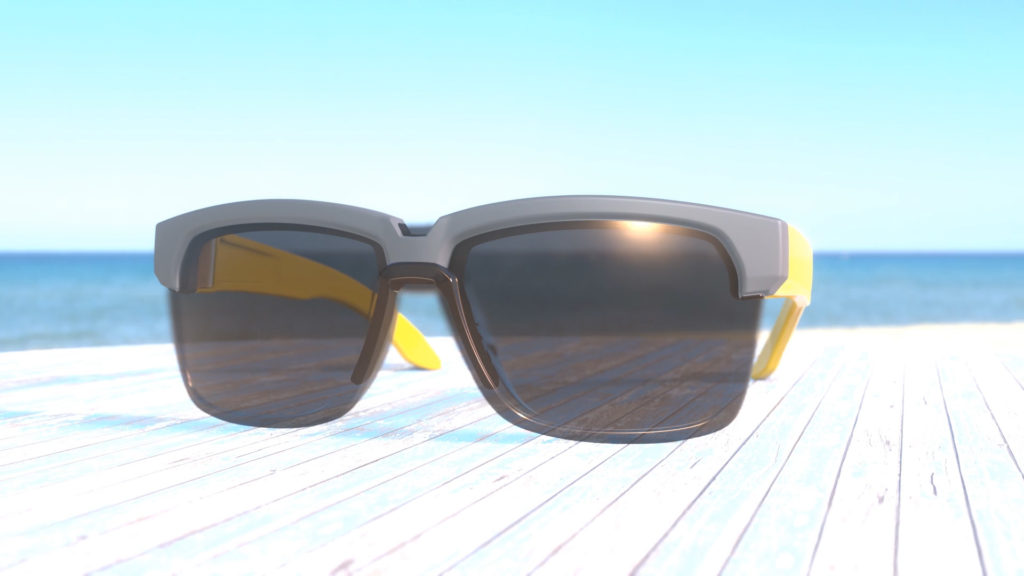

Our eyes are one of our most precious assets. Protecting our eyes during hazardous activities in work environments, sports, and leisure activities has created a market for high-performance and reliable protective eyewear.

Eyewear is manufactured with several components, each made from a different material. The lenses of most eyewear designs are made from materials such as PC or PMMA, with a protective coating for scratch resistance and UV protection. Frames are generally made from lightweight engineered plastics. Comfort components, such as nose pads, end pieces, and temples, are made of rubber materials (such as thermoplastic polyurethane) or LSR. All these components are then assembled in a secondary operation.

But now using our new patented technology, manufacturers can produce eyewear in one piece and with one material. New optical-grade LSR materials combined with a two-shot injection molding technology will eliminate the need for secondary assemblies and multiple polymer material inventory requirements.

Kruse Eyewear Vision Technology

Optical Clarity

Kruse Eyewear technology will allow designers and manufactures to create protective eyewear with excellent clarity and comfort. LSR optical-grade materials provide 94% clarity with low haze and light scattering along with high UV and thermal stability to prevent yellowing and environmental degradation.

Durability

LSR optical-grade materials are impact and scratch-resistant. Because of the broad service temperature service range (-50°C to +150°C) eyewear injection-molded using this technology can be used across a wide range of applications.

Design

Two-shot optical-grade LSR materials allow eyewear designers the freedom to design functional and fashionable eyewear without traditional restraints. Manufacturers will now have the ability to replicate very small design features, reduce overall weight, and provide anti-slip functionality, all in one piece.

Fewer Molding Challenges

Two-shot LSR injection molding has fewer associated challenges than the traditional process. These include reduced molding pressures, resulting in lower residual stresses, the ability for thin wall molding, no secondary polishing of the molded optics, and de-molding with undercuts.